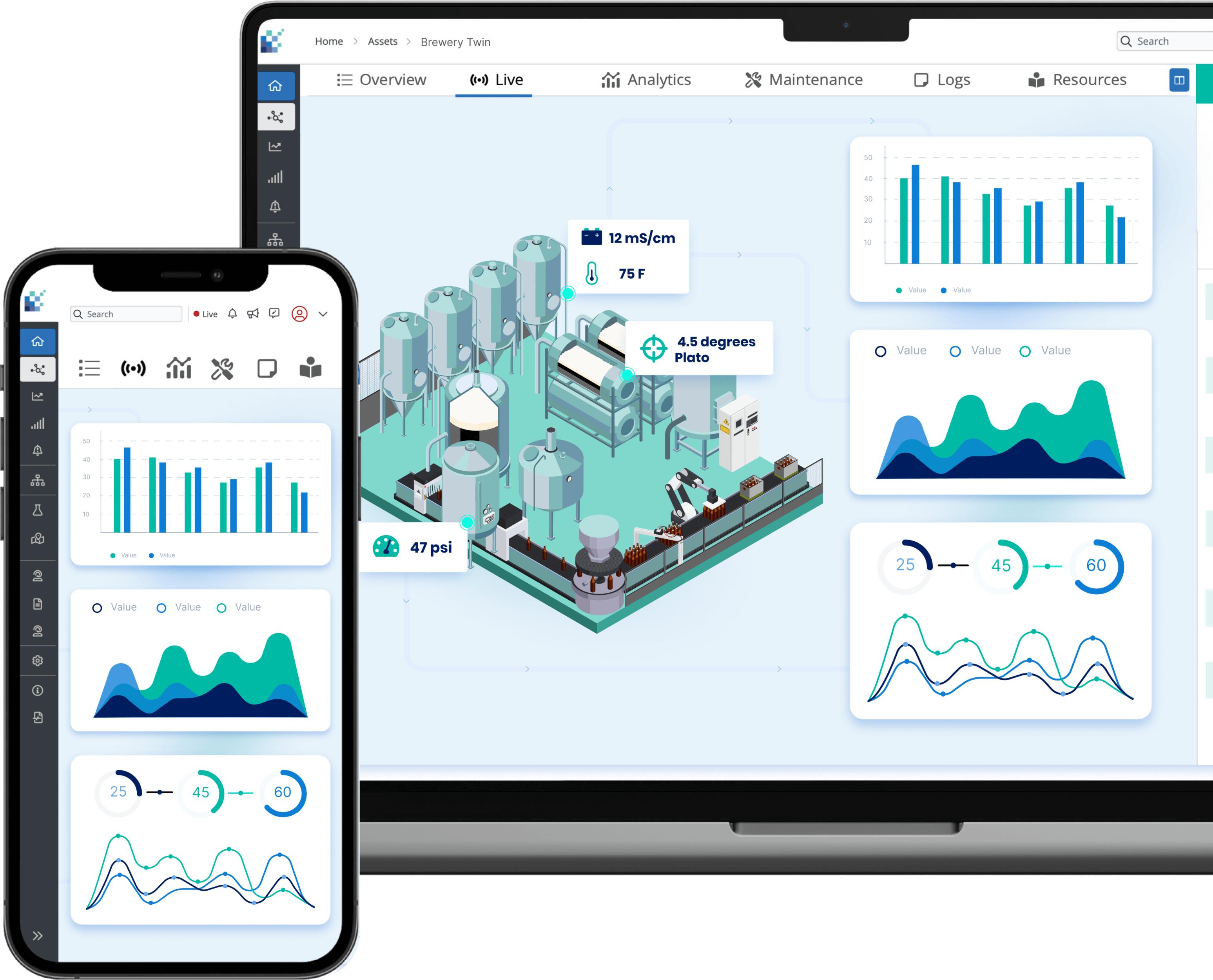

Unleash the power of captive data

Industrial systems are built for "day 1" operation. They are complex and expensive to modernize. Preddio Simplicity solves this problem.

Industrial systems are built for "day 1" operation. They are complex and expensive to modernize. Preddio Simplicity solves this problem.

Uncover unlimited opportunities to improve productivity, increase quality, and reduce unscheduled maintenance. Traditional control systems, designed for day 1 operation, are rigid and difficult to modify, slowing the pace of continuous process improvement.

Preddio Simplicity is:

Free Captive data, Drive Continuous Improvement,

Drive Condition Based Maintenance, Quick, Easy Installation

Preddio Simplicity is super easy to install, but if you need a hand just give us a call. We have experience freeing captive data from all types of industrial systems and enjoy helping customers develop breakthrough solutions.

Unleash the power of captive data, through continuous improvement of your operations and maintenance programs.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |